Water Flow Characteristics — Water-hammer

時(shí)間:2016-07-09 10:39:12點(diǎn)擊:次

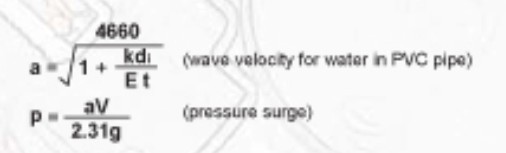

When a pipe contains a column of moving liquid, considerable kinetic energy is stored in the liquid by virtue of its mass and velocity. If the velocity is suddenly destroyed by the quick closing of a valve this energy cannot be absorbed because liquid is nearly incompressible. Therefore, an instantaneous shock is created which may represent excessively high pressures. Maximum pressure caused by water-hammer may be calculated with the following formulae:

Pwh = pressure surge, psi

V = maximum velocity change, ft./sec.

gc = acceleration of gravity, 32.2 ft./sec.2

K = luid bulk modulus, 300,000 PSI for water

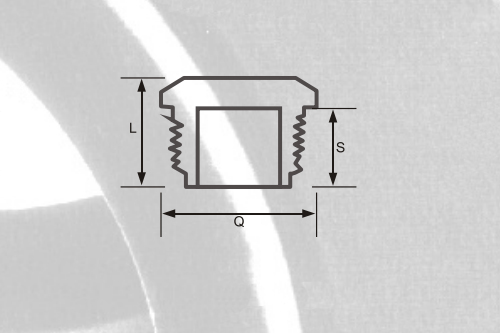

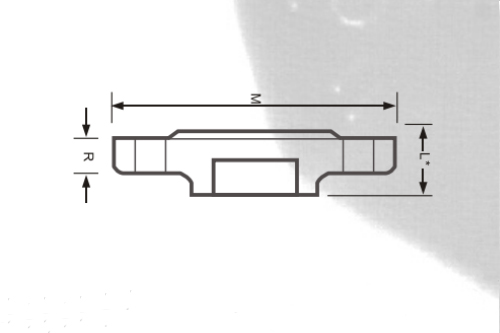

d = pipe inside diameter, inches

b = wall thickness, inches

This is what should be reviewed when a plastic piping system is being considered.

? Speed of opening or closing of regulating type valves.

? Action of pumps starting or stopping.

? Movement of entrapped air through the system.

Understanding the concept of water-hammer and designing the system to minimize it is the best possible preventive measure. A few tips to consider when attempting to reduce the causes of surge in a piping system are:

? Keep fluid velocities under 5 feet per second. (see pages 7.08 ~ 7.11)

? Check the cycling time of valves to prevent abrupt changes in flow. Both manual and actuated valving should be checked for speciic closing times.

? Evaluate low at pump start-up and during spin-down. Also determine how much air, if any, is introduced during pump startup.

? Use properly sized vacuum breaker-air relief valves to control the amount of air that is admitted or exhausted throughout the system.

SPECIFIC INSIDE DIAMETERS OF PIPE

下一篇:Installation Ⅱ

- About Us

Company profile

Culture

Enterprise image

Company honors

Organizations

Video

- Strength

Plant Workshop

Design center

Innovation mode

Quality guarantee

- Standard

Advantages

Usage

Construction standard

Notice

- Technical

- Network

- Contact Us

Mobile Scanning

Mobile Scanning

Wecat Scanning

Wecat Scanning

Copyright ? 2017 Zhejiang Huangyan Minghua Plastic Pipe Fittings Co.,Ltd.All Rights Reserve. 浙ICP備11019802號(hào)-1 浙公網(wǎng)安備 33100302000346號(hào) XML | Sitemap Power By:Galaxy